What is Industrial Abrasion?

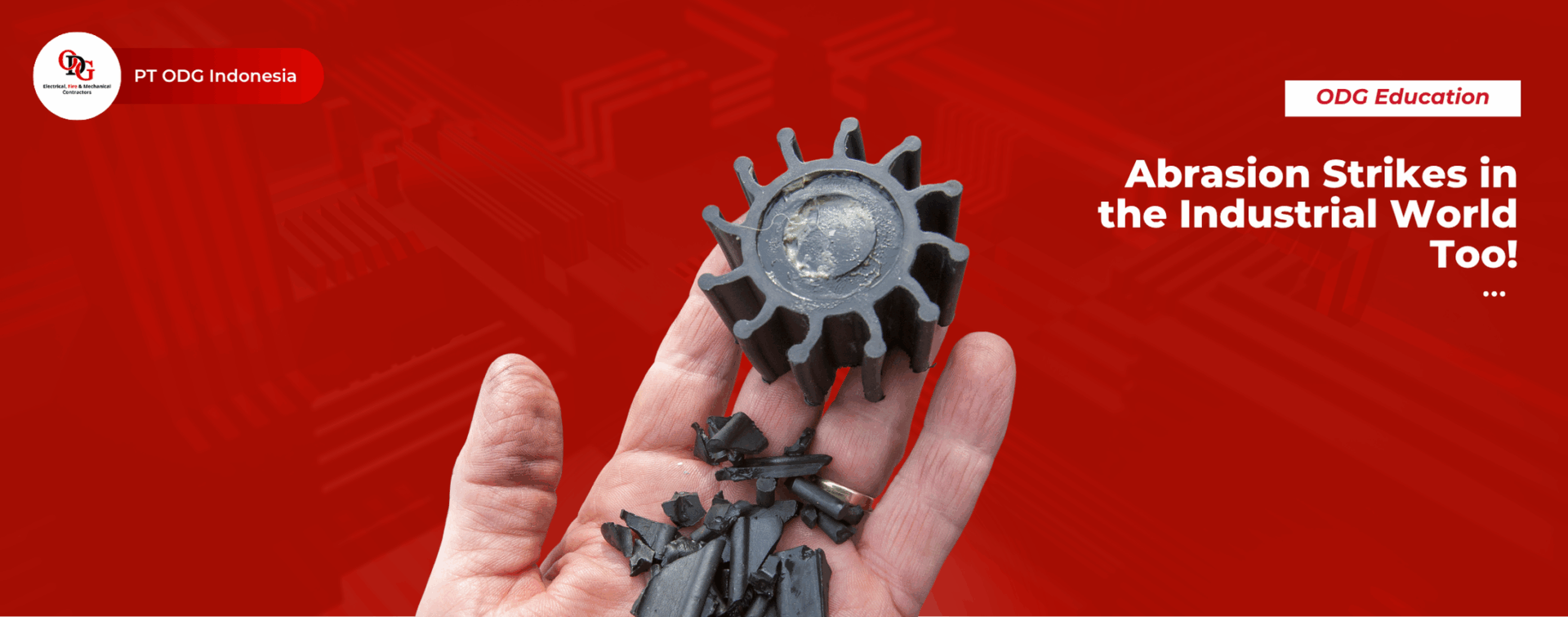

Many people think abrasion only happens at beaches. But industrial abrasion is also a major concern. It occurs when surfaces wear down due to friction or contact with abrasive materials. This affects pipes, floors, machinery, and other components.

Constant friction in operations speeds up surface damage. Exposure to fluids, slurry, or fine particles makes the problem worse. If not addressed, it can lead to serious equipment failure.

Industries Affected by Industrial Abrasion

Industrial abrasion happens across multiple sectors, including:

-

Mining: conveyor belts, slurry pipes, and chutes.

-

Power Plants: turbines, boilers, and piping systems.

-

Manufacturing: production machinery and molding tools.

-

Marine & Offshore: ships, rigs, and underwater pipelines.

Impact of Ignoring Abrasion

Uncontrolled abrasion causes critical issues:

-

Rapid wear and damage on important assets.

-

Increased production downtime and repair time.

-

Higher maintenance and replacement costs.

-

Structural failure or leakage in extreme cases.

How to Prevent Industrial Abrasion

To reduce abrasion risks, companies should:

-

Use abrasion-resistant materials like SIConit.

-

Apply protective coatings on exposed equipment parts.

-

Perform scheduled inspections for early detection.

-

Use engineering designs that minimize surface friction.

Why Choose SIConit as Your Protection Solution

Don’t let abrasion disrupt your operations. SIConit is a silicon carbide-based solution built for extreme wear. It extends equipment life and reduces costly repairs. Discover how SIConit can protect your industrial equipment from extreme wear and extend its lifespan.

Get full information about SIConit here